Knowledge Corner

Mysore Silk Sarees

Mysore silk sarees originate from the state of Karnataka which happens to be one of the largest mulberry silk producers in the country. The growth of this silk was brought...

Mysore Silk Sarees

Mysore silk sarees originate from the state of Karnataka which happens to be one of the largest mulberry silk producers in the country. The growth of this silk was brought...

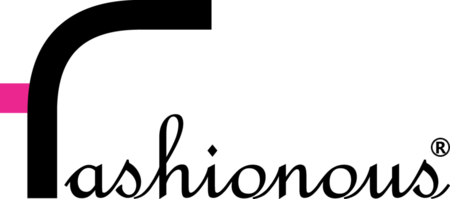

Baghi prints

From the Bagh village in Dhar district of Madhya Pradesh, this bold and vibrant hand block printing technique has been passed down from the Chhippas of the Khatri community who...

Baghi prints

From the Bagh village in Dhar district of Madhya Pradesh, this bold and vibrant hand block printing technique has been passed down from the Chhippas of the Khatri community who...

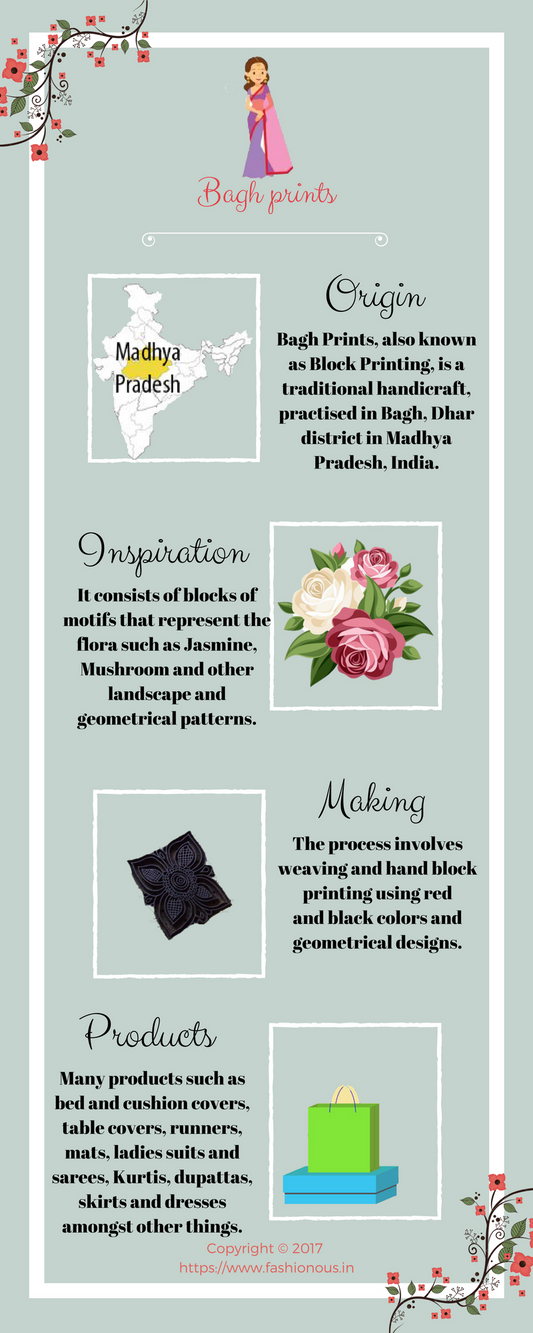

Molakalmuru Sarees

Molakulmuru sarees are a production of a small town, Molakulmuru in the Chitradurga district on the borders of Karnataka. The sarees are stylized with depictions of flowers, leaves, trees and...

Molakalmuru Sarees

Molakulmuru sarees are a production of a small town, Molakulmuru in the Chitradurga district on the borders of Karnataka. The sarees are stylized with depictions of flowers, leaves, trees and...

Chanderi Sarees

Chanderi sarees date back to the 12th and 13th centuries and originate from the town of Chanderi in Madhya Pradesh, India. Initially chanderi silks were used in weaving ‘khilats’, ceremonial robes...

Chanderi Sarees

Chanderi sarees date back to the 12th and 13th centuries and originate from the town of Chanderi in Madhya Pradesh, India. Initially chanderi silks were used in weaving ‘khilats’, ceremonial robes...

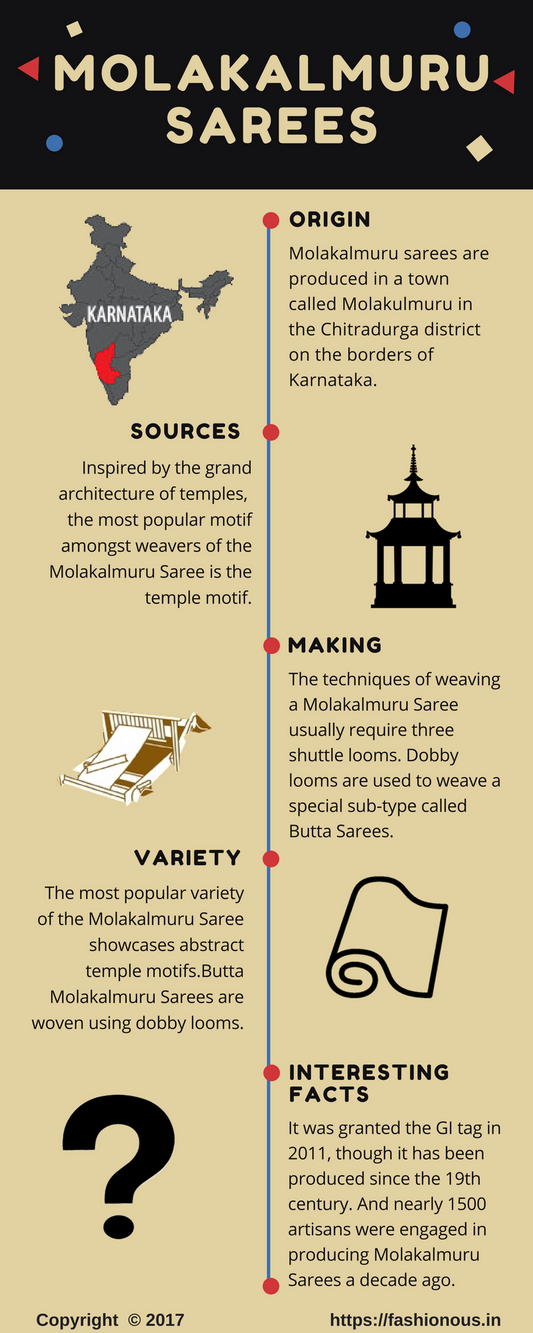

Kotpad Handloom Fabrics

Amongst the variety of handlooms in India, the traditional Kotpad sarees were the first to receive the Geographical Indication of India tag. It is a vegetable-dyed fabric woven by the tribal...

Kotpad Handloom Fabrics

Amongst the variety of handlooms in India, the traditional Kotpad sarees were the first to receive the Geographical Indication of India tag. It is a vegetable-dyed fabric woven by the tribal...